BY Bengt Halvorson—In order to produce affordable electric vehicles at scale, automakers need to both drive down battery costs and secure a stable supply of critical materials. For General Motors and its Ultium Cells LLC joint-venture battery plants with LG Energy Solution, that will be aided by plans to form a joint venture between the automaker and South Korea’s Posco Chemical.

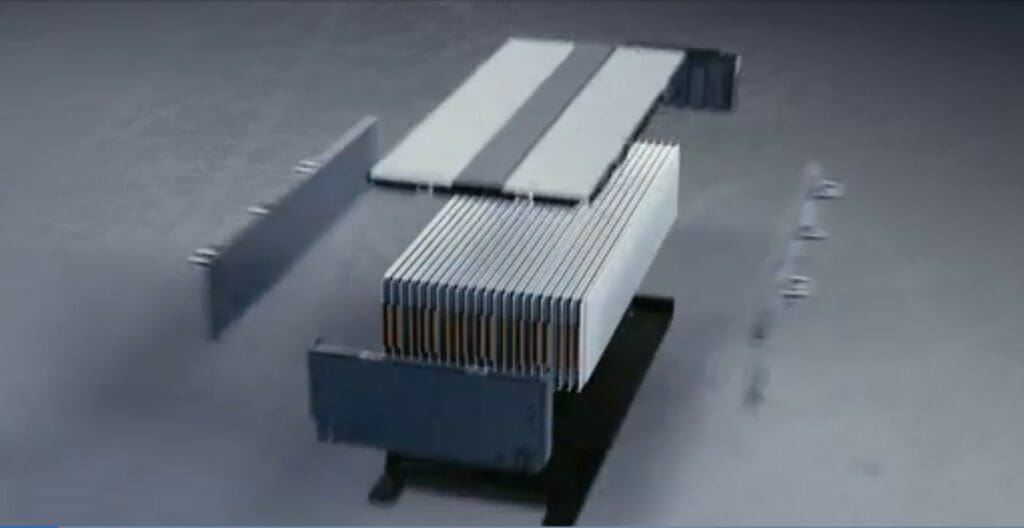

The new joint venture will result in a North American factory that will process some of the battery materials that are so crucial for achieving that scale. According to GM, cathode active material represents about 40% of the cost of the battery cell.

The joint venture hasn’t yet been formed, and GM wouldn’t yet reveal an amount of the partnership or an estimate on cost reduction provided by the venture. But it did say that the plant will add hundreds more jobs.

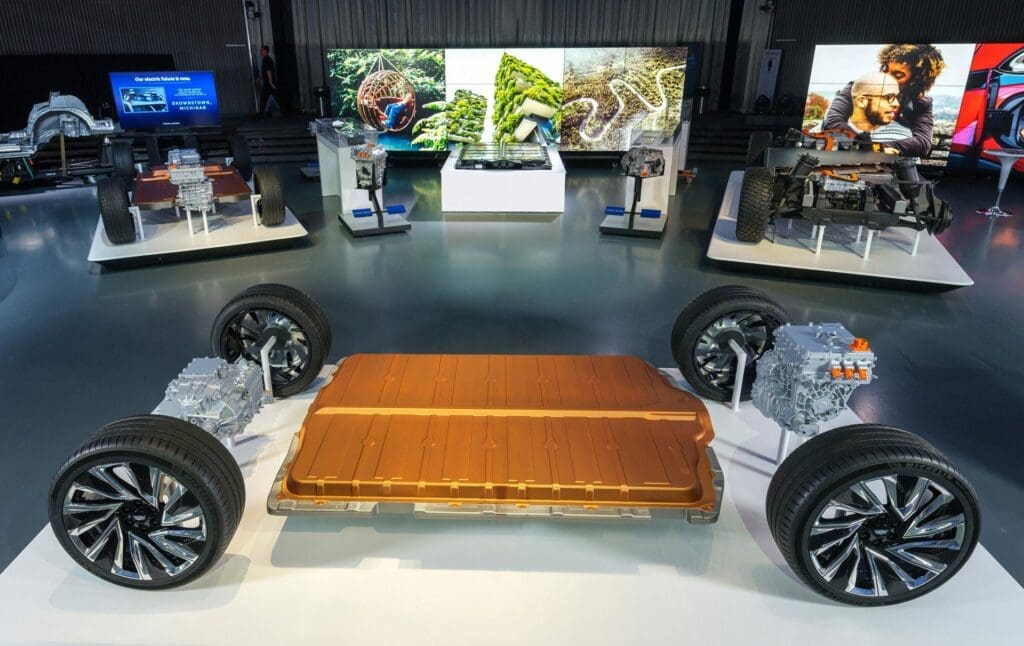

Artist’s impression of Ultium Cells’ battery plant in Lordstown, Ohio

According to Doug Parks, GM’s executive VP overseeing product development, purchasing, and the supply chain, the facility will open in 2024 and supply “a significant amount” of the material for all four of the planned Ultium Cells LLC facilities that produce cells for GM vehicles. That includes plants in Lordstown, Ohio and Spring Hill, Tennessee, with two more planned by mid-decade.

Even though the low-volume GMC Hummer EV and its six-digit price tag represents the first of GM’s new-generation Ultium electric vehicles, GM again emphasized that EV volume is important. It noted that there are “high-volume retail offerings on the way,” including a Buick crossover, trucks from Chevrolet and GMC, a Chevy crossover priced around $30,000, and as Parks put it, “one coming priced even lower than that.”

The cathode material plant will start with material for the NCMA chemistry that GM is focusing on scaling up through the decade. With the additional two plants, GM says it will have a total of 140 GWh of cell production capacity.

“What this means is that by value, the majority of the Ultium platform will be sourced, processed, or manufactured in North America by 2025.”

Doug Parks, GM’s executive VP Overseeing Product Development

It’s part of a $27 billion EV investment by GM to form a North American vertical integration strategy with a stable and resilient supply chain for EVs. There are already at least ten partners in this value chain, the company said.

Among them, the facility will also work with recovered materials from a Li-Cycle partnership, in a project that aims primarily to recover scrap from battery cell production at the new plants. Parks said that as GM is working through issues with Bolt EV pack replacement, it’s first looking at ways to repurpose the original packs for roles such as grid management. If not, GM might potentially look at bringing materials from those Bolt EV packs back into the supply chain, too.

(SOURCE: Green Car Reports. No copyright infringement intended.)